Constructing a Tailored Dredging Machine What it takes

In 2021, a UAE Dredging Industry customer approached HID Dredger about building 2 sets of customized heavy-duty cutter suction dredges.

The customized dredge had to be designed to withstand changeable and complex conditions of the sea.

The customer chose HID Dredges based on our experience and reputation for designing and building dredges to work in difficult and challenging environments.

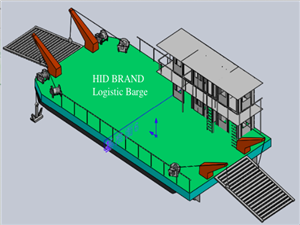

The most significant challenge facing the team from HID was the ability to transport a heavy-duty length of 46m dredge to the UAE port. During the beginning stages of the project, a team from HID's Major Projects division sprang into action and discovered a solution to the problem.

We designed and built a dredge that was capable of being disassembled, easily transported over road and sea, and reassembled at the customer’s project site.

The new customized heavy-duty dredge is equipped with HID's patented 700KW high-power cutter assembly used to specifically target hard coral reefs.

In view of the strong wind and waves in the offshore area, the 2.7-meter deep design and the design of the side hull slope are adopted to minimize the impact of wind and waves on the dredger's work。

Adopt the combination of Mitsubishi 1885kw/1500rpm main engine and Cummins 1007kw/1800rpm auxiliary engine to provide enough power for the dredger to meet the requirements of working conditions.

The dredge will spend most of its time in brine. Due to the nature of work that’s involved the equipment onboard the dredge is suitable for a highly corrosive environment.

After spending several months assembling the customized cutter suction dredge and undergoing testing, the team from HID Dredger is proud to announce that the final stages of construction are now complete.

At end of 2021, a crew from HID Dredger completed disassembly of the dredge. Various dredge sections and components were shipped breakbulk placed on a vessel that set sail for delivery from the Port of China. In addition, HID's team of experienced field service engineers were on site to assist the customer with the assembly of the dredge and training of their crew.